Taper pin: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 99: | Line 99: | ||

</center> | </center> | ||

== Application == | |||

[https://www.google.com/search?q=taper+pin+ibm&ie=utf-8&oe=utf-8&aq=t&rls=org.mozilla:en-US:official&client=firefox-a&channel=sb Bob wrote]: | |||

: When I worked for IBM we still had card machines when I started that used taper pins all over the place. We were issued an assortment of taper pins about 3 inches long in different sizes. The standard procedure was to put a new pin in the hole and ream the hole if necessary. The new pin was marked on each end, then nick the pin with a file just outside the gear or pulley, break off the unneeded ends, dress the ends with a file and drive it home. | |||

== References == | == References == | ||

Revision as of 23:16, 13 August 2014

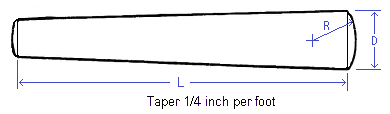

A tapered pin is a fastener used in mechanical engineering. They are steel rods with one end having a slightly larger diameter than the other. Standard inch-sized tapered pins have a taper on diameter of 1:48 while metric ones have a taper of 1:50. A 1:48 taper means that one end of a 4-foot-long bar (48 inches) will be 1 inch smaller in diameter than the other end, or a 1/4-inch taper over a 1-foot length.

The diameter at the small end of ASME Taper Pins is a function of the length and should be specified as a reference dimension for determining drilled hole size. It shall be computed by multiplying the nominal length of pin by the factor 0.2083 and subtracting the result form the basic pin diameter.

| No. of Taper Pin | Diameter Large End D | Approx. Size D | 1st Drill thru size | Second Drill | |

|---|---|---|---|---|---|

| Size | Depth | ||||

| #7/0 | 0.0625 | 1/16 | 0.0469 | ||

| #6/0 | 0.078 | 5/64 | 0.0469 | ||

| #5/0 | 0.094 | 3/32 | 0.0625 | ||

| #4/0 | 0.109 | 8/64 | 0.0781 | ||

| #3/0 | 0.125 | 1/8 | 0.0938 | ||

| #2/0 | 0.141 | 9/64 | 0.0938 | 0.1094 | 1-1/4 |

| #0 | 0.156 | 5/32 | 0.0938 | 0.1250 | 1-1/2 |

| #1 | 0.172 | 11/64 | 0.1094 | 0.1406 | 1-1/2 |

| #2 | 0.193 | 3/16 | 0.1094 | 0.1406 | 1-3/4 |

| #3 | 0.219 | 7/32 | 0.1406 | 0.1719 | 1-3/4 |

| #4 | 0.250 | 1/4 | 0.1719 | 0.2031 | 1-3/4 |

Application

- When I worked for IBM we still had card machines when I started that used taper pins all over the place. We were issued an assortment of taper pins about 3 inches long in different sizes. The standard procedure was to put a new pin in the hole and ream the hole if necessary. The new pin was marked on each end, then nick the pin with a file just outside the gear or pulley, break off the unneeded ends, dress the ends with a file and drive it home.