Some Cylinder Packing Tips

Some Cylinder Packing Tips

by LeRoy Brakke

Itasca, Illinois

The Miniature Locomotive, November-December 1954

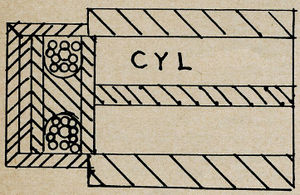

I read Vick Shattock's article on Garlock valve stem packing being use as piston packing on small locomotives. This packing can be had in square, braided, as well as round. I have used this type of packing in my Atlantic engine for years. It works out nice with brass cylinders. A little water left in the cylinder after a run won't do any damage. I prefer one wide deep groove instead of two small ones in the piston head. I put the piston rod in the three jaw chuck and wind 1/8 round packing soaked in valve oil until the groove is filled a little beyond the diameter of the piston. Take a piece of material so that you can make a ring the width the same inside diameter as the cylinder bore. The outside diameter of the ring should be 1/4 inch larger than the inside diameter. The inside diameter should be tapered at one end. Tkae the piston which has been wrapped with packing and work it into this ring, leaving the end sticking through the rings about 1/16 inch so it will start into the cylinderbore. Then tap it gently with a piece of brass against the end of the piston rod. It will be a little tight but a little running will soon loosen it up. It should last for years if kept lubricated.

Attention: Mr. Coventry. I read an article in the January 21 issue of the Model Engineer Magazine that you had written in answer to a request for information about the 50% cutoff that was used on the Pennsylvania RR 2-10-0 back in 1915. In your drawing I CAN SEE how the starting port was used with piston valves, but how would you work it into a slide valve? I have used the 55% cutoff in my engines for years, and I never knew it used on prototypes. The reason for the 55% cutoff is to get off dead centers. I also have converted a 4-6-4 with slide valves belonging to friends of mine. Where they used to make only a few laps on my 275 foot raised track (the only one in the Chicago district) without having to stoke the fire, they now make a half dozen or more laps. As for mine, I have a British type 4-4-2, I used the long lap valve in it for the last eight years.