Priming

Jump to navigation

Jump to search

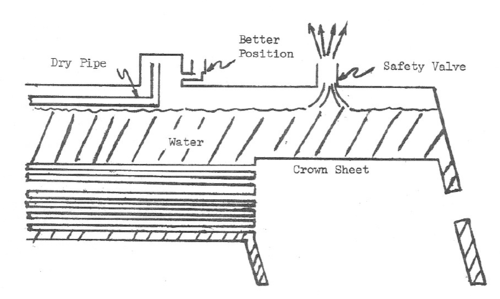

Priming is a condition in the boiler of a steam locomotive in which water is carried over into the steam delivery. It may be caused by impurities in the water, which foams up as it boils, or simply too high a water level. It is harmful to the valves and pistons, as lubrication is washed away, and can be dangerous as any water collecting in the cylinders is not compressible and if trapped may fracture the cylinder head or piston.

From Gary Kubicek Loco-Notes:

- We know that as the pressure in a boiler gets higher, so does the temperature of the water in the boiler. If this pressure is suddenly decreased, the water erupts or violently changes to steam. This sudden decrease in pressure occurs immediately under a safety valve each time the safety valve releases and, if the water is carried high in the boiler, the violent change of water to steam carries some water out the safety valve giving quite a shower - this is referred to as priming. This is not foaming which results from some chemicals in the water which create a form of suds when the water is agitated.

- The boiler outlet to the cylinders must be placed high in the boiler (in the steam dome) to prevent priming. Water carried over through the throttle may loosen a cylinder cover through hydraulic pressure. Superheaters on small locomotives tend to prevent this since the water carried into the dry pipe by priming is changed to steam in the superheater tubes. In some cases a sieve (drilled plate) in the bottom of the steam dome also helps keep water out of the dry pipe as well as providing support for the dry pipe.