Portable Track for a Christmas Train

by Lindsay McDonnell, British Columbia Society of Model Engineers, 2003

At Christmas time in the more northerly parts of North America – and Europe, too, I suspect – most Live Steamers and model engineers have put away their trains for winter and shut down club running until warmer weather returns. The British Columbia Society of Model Engineers used to do that, also.

However, in 1998, with many major construction projects ahead of us to get the track ready for the IBLS 2000 Meet, the executive searched for ways to raise money. Sure, our public running in the warm weather was bringing in a good cash flow, but we discovered a shortfall when we ran the estimates for two tunnels, two large retaining walls, four new, long bridges and a large workshop.

Our president, Ken Klakowich, decided to approach the managers at some of the shopping malls in the Greater Vancouver area to see if they would want a train for the public to ride, over the Christmas period. Most politely said no. But one manager at Lougheed Mall in Burnaby said yes! He had seen our trains at the park in the summer and was very interested. He offered to have us place a railway around Santa’s castle inside the Mall. We told him it was to be a fundraiser for the BCSME; he offered $5,000 to set up and run the train, and told us we could accept donations and keep 100% of those. So we agreed.

So sure was the manager of the success of the railway, he asked for a three-year deal. There was one problem: the discussion was taking place in October; we had to have the train in and running for mid November, and we didn’t have a track built. Our members were very busy with building switches and numerous other projects for our park railroad.

We decided to look into getting a steel fabricating company to make a circle of track. A price of $2,000 to build the circle (including steel) of 16 sections was negotiated by Ken and quickly accepted. So the Mall cut us a cheque for $2,500 as an advance and we got the track made in two weeks. We then decided to get two more sections of curves built, and left and right turnouts, while the company had the jigs. This way we could have a siding if needed at a later date. We had our club boxcab electric loco and plenty of cars, so we were ready to go.

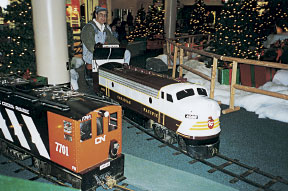

We quickly organized a roster of members and spouses to staff the 38 days. We installed the track one evening, by wheeling in a utility trailer with the track and another with our loco and three (one for standby) 8-foot-long bulkhead cars and a caboose. We bolted the 24-foot radius track together around the already completed Christmas landscape with Santa’s throne in the center. Two ramps were made out of plywood to allow pedestrians, especially those with strollers, to cross the rails and then exit. The track was tied to six big posts in the mall area by using plastic-coated clothesline wire. This stopped the circle of track from creeping. The Mall provided a wooden fence right around the track with a loading and exit opening.

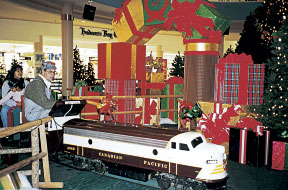

We started operating the day Santa arrived and ran until Christmas Eve, and then from Boxing Day until December 28. Was it worth it? We found we had taken $13,000 in donations plus the $5,000 the Mall gave us. Our outlay was $2,500 and insurance cost $150 (added to our regular policy for our park operation). It had been so successful that we could hardly wait for next Christmas. The second year was even easier. We had the track and train in place in two hours. The club boxcab was used again. It ran flawlessly as it did the year before. When the donations box (an old bus fare box) was emptied for the last time in 1999, we had $17,000 plus the $5,000 from the Mall. Jubilation! We had big expenses building the workshop and bridges at the track for the IBLS Meet of the Millennium and this eased our worries. The third year we did the same, except Paul Roy loaned us his battery-electric 24v CPR F7 complete with digital sound. We put the boxcab in the siding for standby use.

Bruce Wilson, our treasurer, came in every evening and collected the coins and bills. He checked to see that the loco was put on 12-hour charge. Sorting, counting and packing the coins into rolls for banking was a major job for Bruce. He figures he took 416 lbs. of coins to the bank.

Running was from 10 am to 10 pm most days. Bruce also made up the staffing schedule with four-hour shifts once a week for most members. Some members wanted more hours. What else do you do in the rain or snow anyway! For year 2000, we took in $18,000 plus the Mall’s $5,000. So a grand total for the three years came to $63,000. Better still, the Mall wants us back for 2001, and the next year?

Here are more details to give you a better look at our operation – especially if you’re thinking of getting this going for your group:

You need a battery-electric loco of some sort. It doesn’t have to be very powerful as you are pulling only about 14 people maximum on flat track. Once the train is started, little tractive effort is required. You need a charger that can put out at least 15 to 25 amps for 12 hours. For the boxcab, we have a Lester 24v, 25amp charger with a timer that has served us 23 years so far.

We used our club bulkhead straddle cars.These have a padded seat board, are 8 feet long, and will hold seven people each. If you use typical gondolas, you need about five. Put a caboose at the back for looks. Half the passengers will be adults, usually parents and grandparents. Unless you are in a huge mall this should be enough cars. Have a spare car stored. Our club cars all have machined 4140 alloy steel wheels. These are cut from a 4-1/2" diameter annealed 4140 bar and CNC turned. There has been no wear to speak of in six years on our two-mile park track or on our inside track. Our locos are fitted with tires of 4140 also. To cut any squealing of wheels, we rub a candle along the inside edge of both rails in a few places about once every two days. Grease is too messy. Mall personnel laid indoor/outdoor carpet on the tiled floor to pad under the rail. This cuts noise and wear and looks better.

Our track was made from 1/2x1" hot rolled steel bar with 1-1/2 x 1/4 x 15" steel ties welded on 8" centers. We widened the gauge to 7-11/16" to make sure there would be no binding and extraordinary wear. Our track had to be 24-foot radius at the center line. So we had 16 sections to make a circle, just like an HO tabletop track. The joints are parallel; each section was welded in a jig to make sure any section would mate with another and we didn’t have to number them. Two extra curves were made later for sidings, as were a left and right switch. The curved section of these matched the other curves, so we can put it in on a curve and have a siding. We figured we can make the straights if needed. We used only one switch, and the curved rail it replaced was the siding to store the fully charged standby loco. We bolted them together with 1/2" bolts and Nylok nuts. Then we wired around posts to hold it all in place.

On the operating scene, we asked all engineers and helpers to have at least a railroad cap to identify themselves. Most engineers had coveralls too. A ride consisted of four laps of the 150-foot circle. We figured we did 16,000 laps for a distance of 455 miles over the season. We had printed out a one-sided “brochure” (three to an 8-1/2 x 11" sheet) with a blurb advertising where our park track is and when it operates, and offering a free ride if you buy a ride ($2) printed on the bottom. The slip is given one per family. The free ride is good for the year printed on the flyer. This had the effect of informing those who didn’t know where our track is, and giving a freebie also encouraged them not to throw the slip away and to donate freely once they arrived. When it’s for a non-profit club and the public knows what it’s for, they are inclined to donate more. We gave out nearly 6,000 flyers and expect about 1,000 to be redeemed.

The person who loads and gives out flyers carries out a most important task. Many wives helped here. Their friendly manner, coupled with talking to those waiting, makes for good Christmas camaraderie. We often swapped around the driving. However, it is possible to operate the railway with one person if need be.

We had so many families come and ride many times. Some came back to the Mall where they normally didn’t shop, just because of the train ride for the kids. A big, elaborate track isn’t needed. Having a Santa nearby helps the cause, but they have to visit him only once; the train ride they can repeat many times. This was music to the ears of the Mall management. So we are invited for a fourth year! All those who put in four shifts or more were taken out for a dinner at a good restaurant in January.

Now, I tell you this so your club can probably raise more funds running in a mall during Christmas than it can raise in a whole year on your outdoor track. And it’s FUN. The exposure your club will get will only be beneficial. All the naysayers might try to pour cold water on the idea, but you have my word on it – it’ll work for your club too, and you may pick up some new members. You can even get non-club members to help.

Never venture, never win!