Petticoat

by "North Eastern"

The Live Steamer, September-October 1950

The question has been asked in an issue of The Live Steamer, "What purpose does the flared out bottom extension of a locomotive stack server?"

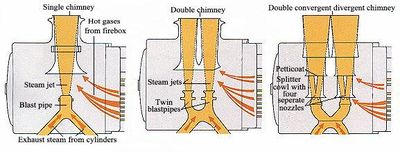

To induce the draught necessary in a locomotive firebox, exhaust steam is directed up the smokestack creating a vacuum in the smokebox and drawing air through the grate bars and fire. All gases, and we can regard exhaust steam as a gas, emerge from an orifice in the form of a cone whose total angle is approximately 10 degrees. For efficient draughting, steam from a locomotive exhaust pipe must completely fill the stack. In earlier days when stacks were tall and shapely (there were some monstrosities I will admit, but internally at least they were all similar) the 10 degree cone of exhaust steam had no difficulty filling them. Boilers, however, got fatter and stacks shorter and shorter until, unless something was done about it, the exhaust steam would pass right out to the atmosphere without going anywhere near the sides of the stack. So designers began to extend the smokestack inside the smokebox instead of outside, to provide sufficient length for the 10 degree cone to fill. Also since the smokebox gases had to be ejected by the exhaust steam, the bottom of the extension was usually flared out to a varying degree to allow the gases easy entry to the stack.

The "smokebox extension" (its actualy name on many roads), or "petticoat pipe" is actually a portion of the smokestack, compensating for the almost (in some cases) non-existent stack to be seen outside. The amount of flare at the base seems to be one of those questions never satisfactorily answered. Much experimenting was done all over the world, but every railroad apparently still has its own ideas.

Petticoat pipes were often made up in series, one above the other making as many as four or five separate flares. That type of petticoat is still common on certain oil burning locomotives.

In my own experience, the amount of flare doesn't matter much. Some of the best steaming locos I ever knew had petticoats with no flare at all to speak of and a diameter at the bottom of only 11 inches (I got stuck in one once). They projected into the smokebox as part of the stack casting.

Blast Template

The Live Steamer, September-October 1951

Last month's query concerning the correct height of exhaust nozzle in the smokebox and how it affects the burning of the fire has not brought forth an answer by anyone. Therefore, for the interest of those that might like discussion on the subject, a few general comments by the writer might be in order, though the writer is not up on all the right answers to this subject, it can do no harm to state some of the facts known, along with some others as well.

The blast nozzle is usually located approximately one third of the smokebox height up into the smokebox and approximately in line with the middle of the tube rows as near as possible. However, there are various factors that influence this height location and the most important point is that the exhaust steam completely fill the stack as it exists. To get this desired effect a template is made up with a 6 to 1 tapered cone which is placed into the stack with the pointed end of the template resting in the nozzle and the upper end of the template should touch the stack inside edges just slightly below the stack rim. If the nozzle is set too high in the smokebox the upper part of the template will not touch the stack sides and the nozzle must be lowered until it does. If the nozzle is set too low the template will rest into the stack but will not reach the nozzle at its lower end, so the nozzle must be raised until the template rests in the nozzle.

Another further template with a 3 to 1 cone angle is used in conjunction with this first template. The second template is made with straight edges at its uppermost end to fit freely into the stack liner and when dropped into the stack with its lower pointed end resting in the exhaust nozzle the upper end of the 3 to 1 taper cone where the straight section of template starts should be touching the inside of stack at a point slightly above the lower end of the stack petticoat pipe. The use of these two templates will insure that the exhaust steam correctly fills the stack for the best effects on the fire and if the steam does not fulfill these conditions the engine will not steam well even to the point of failure in some cases.

Some other interesting things about the location of the nozzle height. For instance it is known that if the nozzle lines up with the bottom tubes the draft will pull more on the front end of the fire and if set high opposite the opposite the upper tubes, the fire will burn better at the backend of firebox. So in most cases it is best to set the nozzle as near as possible to the middle row of tubes. On the other hand, Carl Purinton favors setting his nozzles as low as possible in the smokebox and it is presumed that in doing this his stack has to be of a larger inside diameter to get the right combination of factors for the steam to fill the stack correctly. These comments are the writer's thoughts and in now way a qualified answer.