How An Injector Works

See also Injector.

- Last month (February 1976) I mentioned an article appearing in the Riverside Live Steamers Chronicle, written by Dick Bagley, and entitled "HOW AN INJECTOR WORKS," and offered to print it if there were enough requests. Harry Dixon sent me a copy, although I had saved one myself, with permission from Dick to use it, which is not a request. It means, "print or else..."

- Bill Tuggle, Editor

By Dick Bagley

The usual explanation is that an injector works because the steam imparts sufficient velocity to the water to overcome the pressure of the boiler. That is true, but is simply a statement of fact and gives no clue as to how we might have discovered the answer. So, now you have your finger on the puzzle. The answer tells you "why" an injector works and now you should just like to know "how" it does it.

We'll first take a look at some of the goings on the inside of a boiler. Assume the internal pressure to be 180 pounds. That will be 180 pounds per square inch whenever it is measured. A thermometer placed inside will show that the surface water and the steam are at the same temperature, 379°. But the steam contains more heat than the water. After the water is heated, it requires still more heat to break up the drops of water to make steam. This heat is stored up in the steam and is known as the transfer of energy. The stream not only exerts a pressure of 180 pounds per square inch, but can also expand eight to twenty-six times its original volume. Water under the same pressure would be discharged in a solid jet with no expansion. One pound of steam is capable of much more work than one pound weight of water because of the heat which has been used to change it to steam. This can be seen by comparing the velocities of discharge from a steam nozzle and a water nozzle, both under 180 pounds of pressure. Steam will expand while issuing, and reach a velocity of about 3600 feet per second (fps) at the end of the nozzle. Water, having no expansion, will have a velocity of only 164 fps, only about 1/22 of that of the steam.

If a steam or water jet comes in contact with the body in front of it, the tendency is to drive the body forward. The force which tends to move the body is called "momentum" and is equal to the weight of water or steam discharged by the jet in one second multiplied by its velocity per second. If one pound of steam is discharged per second, the "momentum" will be 3600; 1 multiplied by 3600 equals 3600. It would require 22 pounds of water to do the same, because 22 multiplied by 164 is nearly 3600. Both are discharged under the same pressure, but the steam has 22 times the force or "momentum" as the water jet could easily enter a boiler at 180 pounds of pressure if we could reduce it to the size of the hole of the water nozzle.

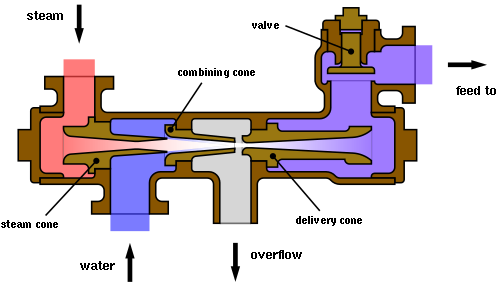

So we've hit a little problem. Our steam jet expands. Even at the most narrow part of the nozzle, it is more than 16 times larger in diameter than a water jet discharging the same weight per second. The trick, then, is to change the steam to water without reducing its velocity. The simple way to reduce its size is to condense the steam. Water is good for this purpose, and we need some water in the boiler — so why not? To condense the steam and utilize its velocity the water must be brought into close contact with it without interfering with the direct line of discharge. A funnel, or "combining" tube, suitably placed, will compel the water to enter evenly all around the steam jet. The mouth of the funnel must not be too large or too much water will enter and swamp the jet. If too small there will not be enough water to condense the steam. The effect of condensing the steam is to reduce the diameter of the jet. Therefore the combining tube must be a smooth converging taper to lead the combined jet of water and condensed steam into the smaller hole of the delivery tube. The effect of the impact of the steam is to give the water its momentum, so that a solid stream will issue from the end of the tube.

Each little drop of water entering is driven faster and faster by the vast number of little atoms of steam, moving hundreds of times as rapid, until the steam and water combine into one swiftly moving jet of water and steam, which contracts sufficiently in diameter to enter the small delivery tube.

The combined jet now passes from the end of the combining tube into the delivery tube.

The delivery tube is merely a nozzle. Remember now what we said about nozzles and velocities in our fourth paragraph. First we need to know the velocity of the combined jet at the end of the combining tube. If the steam nozzle discharges one pound per second at 3600 feet velocity, the momentum is 1 multiplied by 3600, or 3600. If the vacuum caused by the condensation of the steam lifts and draws into the combining tube, ten pounds of water per second at a velocity of forty feet, its momentum is 400. Add this to the velocity of the steam and we have a combined velocity of 400 plus 3600, or 4000. The weight of the combined jet is eleven pounds.

When it enters the delivery tube its velocity should be equal to 4000 divided by 11, or 363 feet per second. Since the steam and water do not meet in exactly the same line of discharge, there is a loss of momentum, and the velocity in the delivery tube is only 198 feet per second. But the jet only needs a velocity of 164 feet per second to enter the boiler carrying 180 pounds pressure. The actual jet in the delivery of steam, because of the velocity of a jet of water under a head of 206 pounds would be 198 feet per second. This excess is more than enough to overcome the friction of the delivery piping and the resistance of check valves.

Perhaps that answers your question, Merrill. And as a little added feature, we also know why hot injectors fail, or — most often — why we cool an injector sometimes, in an effort to make it work.

Thank you..., if you got this far.