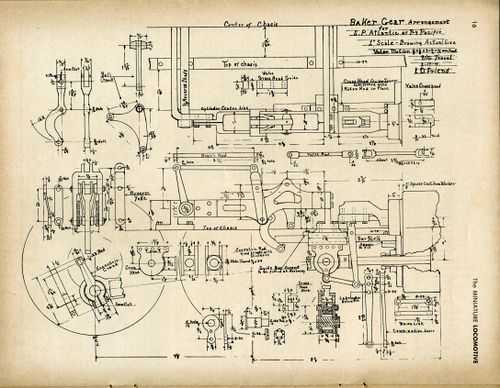

Baker valve gear

Jump to navigation

Jump to search

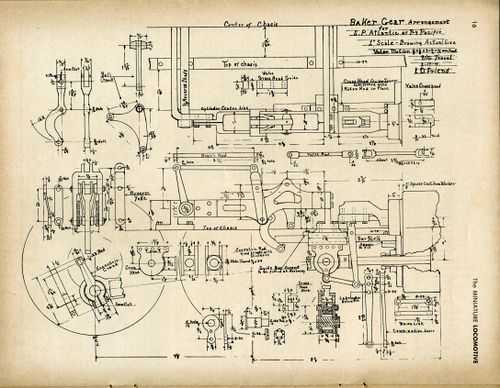

SP Atlantic

Baker valve gear drawing for 1-inch scale SP Atlantic by Lester D. Friend, from "The Miniature Locomotive", May-June 1953.

Berkshire

Jim Kreider posted on Facebook, August 2018:

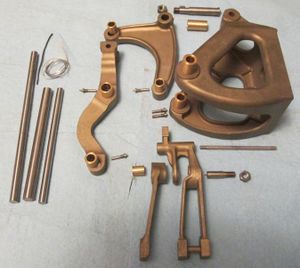

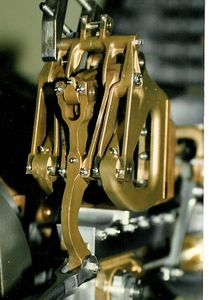

- Here's some photos of the pin and bushing sets that I made for the Baker Valve Gear and sold along with the gear if a builder wanted them. Basically I have precision machined drill rod pins running in 660 bearing bronze bushings. Since you shouldn't press bronze bushings into bronze castings, I made precision slip fits between the castings and bronze bushings and then used bushing retainer pins to keep the bushings from rotating in the castings. The retainer pins sometimes were made to look like Alemite grease fittings as used on the prototype. Non-metallic thrust washers were used between interfacing bronze parts.

- The design seems to have worked out well as there are many gears out there with many miles on them and showing little wear when using light machine oil on the gear pins. These pin and bushing sets were probably the first use I made of commercial CNC work.

- The prototype used "fiber" thrust washers. The prototype NKP engines used Pilliod needle bearings while some other roads did indeed use bronze bushings.

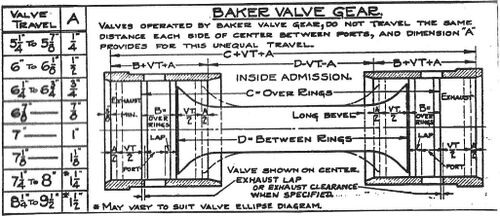

Not Symmetrical

- Baker Valve Gear does not travel the same distance either side of center between ports. Baldwin made the front and back bushings different lengths to compensate. They gave you a dimension to add to one end and subtract from the other end. Here is the diagram from Baldwin Standard Practices.

Setting

Rules for Timing Locomotives with Baker Gear

From Friends Steam Models Catalog 5A:

- Block up wheels in running position.

- Get front and back dead-centers on crosshead and mark these positions on crosshead and mark these positions on crosshead guide with a fine scratch line. (This measurement should be obtained by turning the drive wheels by hand. Always turn them in the same direction.)

- make two "dummy" pins, one for the gear connecting rod lower pin hole and one for the eccentric crank pin hole, these pins to have small No. 60 drill hole in the center for dividers.

- Set the gear connecting rod in mid position, so that the reverse yoke swings back and forth without moving the bell-crank.

- Use a pair of accurate dividers: set the position on front dead-center (by turning the drive wheels). Measure from the center of the pin in the gear connecting rod to the center of the pin in the eccentric crank. Repeat the operation with the piston on the back dead-center. Move the eccentric crank until both show the same measurements.

- To check the measurement of the eccentric rod, set the crosshead on front dead-center. Move the reverse yoke back and forth; the valve should not move. The same holds true for the back dead-center.

- Now set the valve on the valve rod adjustment to have equal "leads" on front and back dead-centers, when the reverse yoke is in mid-gear.

- Precision cannot be over emphasized in timing a locomotive.