Adventures of 486

In this column we'll following the adventures of Allen Mogul #486.

Construction

No. 486 was built, or rather finished, by Robert Donckels of Mololla, Oregon. He bought the loco from someone at Train Mountain who could not build it. Robert is a machinist, and this is his 5th engine. The previous owner bought it from someone who passed away, it is actually 20 years old (1991) but never fired until Robert completed it in 2010.

Gone to Texas

Robert decided to sell No. 486, mainly due to his arthritis. It was becoming increasingly difficult to sit with bended knees for long periods of time on the locomotive tender.

Daris A Nevil noticed the locomotive being offered for sale on eBay in the summer of 2011. Later in the fall it was listed again. Daris contacted Robert, worked out the details, and committed to purchase the locomotive.

Daris and his wife, Marianne, flew to Portland, Oregon in December 2011. They rented a 10 foot moving van and met Robert at the Pacific Northwest Live Steamers in Mololla, Oregon. They loaded the locomotive and supplies (including the Toolbox of Requirement) into the van and headed for home. Daris tells the following harrowing tale:

- Marianne and I drove out of the club lot and went a block down the road. As we were passing a car I ran over a bump in the road raised from the root of a tree. It rocked the truck from side-to-side pretty violently. We heard a loud "clunk clunk" in the back. My heart stopped. I feared that the engine had toppled over. I stopped and opened the back door and saw ... that everything was just fine. Whew. I was so relieved. From then on we were very careful about pulling into and out of driveways, to make sure we did not rock the van.

After three days of travel the couple arrived back home in Texas with their new pride and joy.

Bagley Oil Burner

Replaced the Peterson oil burner with a Bagley Oil Burner.

Toolbox of Requirement

Everything that is is needed for #486 is in the Toolbox of Requirement.

New Oil Tank

The old tin one gallon gas tank finnaly gave out, so a new tee-shaped oil tank was built and installed.

Repairs

Pony Pivot Repair

A derailment due to a branch across the rails damaged the pony truck described here: Allen Mogul Pony Pivot Repair.

Pony Wheel Damage

14 March 2014

I'm pretty hard on my Allen Mogul #486. Seems like every time I take it out to a meet I break something.

The most recent damage happened at Houston Area Live Steamers Chugga Chugga Chili fest. We had a great meet, enjoyed some hot chili, and drove trains all day.

During a run #486 hopped off the rails at a turnout. It went half way onto the wrong turn. Took a bit of work for me and my passenger, Spence, to get it lined back up on the rails.

I didn't take time to inspect for damage. Everything seemed fine, so I continued to run throughout the meet. At one point I heard a squeaking noise up front, but again I ignored the warning sign.

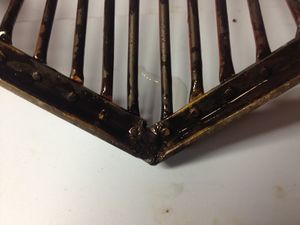

I didn't discover what was wrong until I loaded up after the meet. What I discovered is shown below. During the derailment the cattle guard caught the frog or one of the guard rails and was bent back about 3/8". The brace between the apron and the cattle guard was bent down and started rubbing against the flange of the pony wheel.

By the time I loaded up the flange had been worn to a fine edge. Looks like I will have to turn a new wheel.

But hey, that's part of the fun of the hobby too!

This evening I began work on the damage to #486. My first try thought was "I bet I can hammer the cattle guard straight with a rubber mallet.". Well, after a few whacks I decided that was not going to work out.

Removed the cattle guard and used my 30 ton press to straighten out the kinks. The engineer's side brace was bent, along with the bottom of the guard. A few well placed pressure points straightened it right up! Looks as good as new (except for the paint).

The point of the guard was cracked. It had been brazed when it was made. I don't have brazing equipment, but I do have a Lincoln AC225 welder. I used a small rod, set the current to 70 amps, and welded the joint from underneath. I'm not a professional welder, but it turned out ok. It should be strong. 70 amps was a little too high; it melted part of the edge of the brace. I should have used 60 amps. or even 40 amps. But, the weld will hold, and I think it will look fine after it is painted.

Here is the worn wheel and the new blank, part number M300. I found out from Marty Knox that the M199 and M300 are the same casting. After I got off the phone, I saw the note on their price list that says the same. Duh!

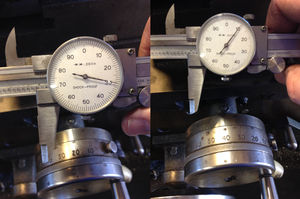

The wheel gauge shows the back-to-back dimension is correct, per the IBLS Wheel Standard.

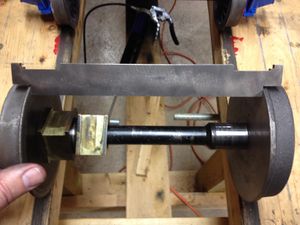

Machining the tread and flange of the new wheel. I know this is not the best setup. Typically you would machine "between centers"; a live center in the tailstock and a dead center in the headstock. I don't have a "dog" that will transfer motion to the axle, so I am using the 4-jaw chuck. The TIR (Total Indicated Readout) is adjusted to less than 0.0005 inches off of the bearing surace of the axle.

I use my dial calipers as a poor man's DRO (digital readout). I take an initial measurement with the dial calipers. With each cut I decrease the dial calipers by that amount. I continue taking 20 mil (0.020 inches) cuts across the tread until I am within 40 mils of the final measurement. Then I stop the lathe and take a measurement, and slowly "sneak up" on the final measurement, taking 10 or even 5 mil cuts.

What kind of cutter is this? Here is a trick l learned from an experienced machinist. The surplus store where I purchase tools did not have a cutting tool with the proper diameter for the flanges. The machinist said "you have to improvise with what you have", and suggested I use a corner milling bit with the correct diameter. Sure enough it works great! The final cuts of the tread and the shaping of the flange were done at 300 rpm.

Water Fitting

The tender fell off the Wesco lift while I was loading it in the van. It fell about 4 feet. Luckily it bounced between the engine stand and the lift about 3 or 4 times on the way down, which minimized the impact. It broke the water fitting on the tender going to the injector.

I turned a new one out of a standard brass fitting.